This week I’m at SXSW Eco to soak up sustainability knowledge. Everyone calls it the “sister event” to its bigger and ‘bandier’ musical sibling, South by Southwest (SXSW). To me, it feels more like an idealistic only child. If Southwest Airlines and its boundary-pushing competitor, Virgin Atlantic, got married, it would make something closer to SXSW Eco.

The agenda was packed with molecular biologists, agriculturists, chemists, and corporate heads of sustainablity – all working to solve complex and massively important issues in their respective industries. So awesome, I just wasn’t sure if there would be a viable opportuntiy for me to connect wtih anyone in the fashion space.

Then I found a gem subtly tucked in between the keynote talks – “Will the Next Alexander Mcqueen be a Biologist?” – and I thought, “heck yes, a fashion reference!” Judging by the descripition – it was loaded with words like biotech, synthetic DNA, embedded electronics that I was wasn’t as familiar with, and others, like closed-loop systems and transparent supply chains that I knew a lot about – it sounded interesting. I’d already read a lot of the news articles about recent biotechnology industry developments, like the huge investments made be Lindsay Rosenwald, so I was sort of familiar with it and looked forward to learning more.

I was keen to learn more and share the knowledge with you. So I caught up with the speaker, Debera Johnson before her session to ask some questions. We talked about her work founding the Brooklyn Fashion + Design Accelerator (BF+DA), fashion entrepreneurship, sustainability, and new technologies that are changing the shape of the industry.

I’ve also added some notes about biotechnology from her talk at the end of this interview.

Our Talk

Let’s start with Pratt Instutite. Can you tell me about your work there in sustainability and fashion?

I’m not from the fashion world – my mom and sisters are. They read WWD cover to cover and know all the top designers, so I have that appreciation. But for me, the environment has always been my core value and I saw it as an opportunity to influence in a much larger way.

I started out as an entrepreneur right out of high school and then landed at Pratt, where I earned a degree in industrial design. Eventually I became chair of the Industrial Design program and helped found the Center for Sustainable Design Strategies (CSDS) [sidenote: this is a on-campus resource for Pratt students that helps ensure they understand the impact of their designs. It operates via a coalition and sustainability reps from each department that share what they’re learning about sustainability across disciplines].

That’s when I stared to see really creative people with ideas that didn’t translate out of their portfolios after graduation. They were lacking in resources to make them viable in the real world. That’s why I created the BF+DA – to serve as this bridge to scalability.

I built in sustainability from the outset because I didn’t want the want designers to struggle with reversing negative practies after they built their businesses. Ninety percent of the impact of a product is determined in the design phase – so this part was critical. At the BF+DA, we’re teaching according to a 21st century model that emphasizes technology, ethics, production and, most importantly, collaboration.

Was there a pivotal moment that inspired you to start the BF+DA?

Yes. I had a student come in and say to me, “You teach us to be entrepreneurs and then you fire us after we graduate. Give me a real problem to solve and I will.”

Why the focus on fashion vs. the other design sectors?

Because there’s a lot to do here. There’s so much that’s gone wrong in the textiles and apparel industry that can change. It’s the second most polluting in the world. The CSDS worked to create a decision making tool for designers that helps them with questions of sustainability and ethics. We’ve incorporated this into the process at the BF+DA to help address these issues from the very beginning of the process – it’s a progressive step forward for the industry.

How is the BF+DA different from other incubators?

Two reasons. First, we take a three-dimensional, systems based approach that emphasizes zero waste, transparency and humanity. Dollars aren’t the only way to measure success and that’s a core tenant of the BF+DA. I like to call it a “hub for ethical fashion.” If you have been looking at using incubators yourself in your work, here’s a professional incubator that may be of help to your projects in this area.

It’s also much more rigorous. We go beyond the idea of shared workspace for designers. Each of our “venture fellows” goes through business and sustainability mentorships and has access to pretty advanced development and manufacturing resources. We have technology [that I’ll talk about tomorrow] in our lab that opens doors to alternative production like 3-D printing, computerized knitting, laser cutting and, eventually, we hope – biotech.

It’s truly a place where a designer can take their products from “made by me, to made by others.” We have to coach most on the numbers, but once a designer understands what it costs to make what they’re making and still take home a profit our job is usually finished.

Designers are really smart people for such a small sector of the economy. They say the only thing that stops a them is a deadline.

We serve as the people who make them accountable and we’re also able to be their cheif sustainability officer. That’s the differentiator, our deep expertise.

Let’s talk about the elephant in the room – cost. How much more expensive is it for designers to produce sustainably? Are you helping them navigate the cost?

It’s scale that gets in the way more than cost. It’s really hard for an independent designer when they only need, say, 30 of something, to place an order. This is why we have a production facility. They can come to us to get the textiles and we can also help point them to most ethical resources that they can afford depending on where they are with their business [From Kasi: this is where that CSDS decision making tool similar to Synario‘s scenario planning one comes in].

The BF+DA helps them build sustainability into their line gradually. There’s always going to be certain things you can’t fix due to cost. For new designers, we often start with packaging, learning about Pro-Tect Plastics and other kinds on the market, and then move through their entire supply chain as they grow.

It’s also about finding a target market and then designing where you can get a price point that allows for sustainability. We talk a lot about this from the beginning with our venture fellows.

Our goal is to get them from making around $30K per year into a profitable range of $300-500K. So far, we’ve worked with 35 different companies and increased collective revenue close to $2 million for 15 of our venture fellows.

Can you tell me the story of a successful designer who has been through your program?

Yes, Mandy Kordal of Kordal Knitwear. She came to us with beautiful products and a great website, but needed that boost, again, to go from “made by me, to made by others.”

Now, she’s being distributed at Shinola and we’re excited that she’s moving close by us in the Brooklyn Navy Yard. She’s still involved in the incubator and helps mentor our new fellows.

You focus a lot on entreprenues, but what is one thing that consumers can do to help with sustainable fashion?

Wash your stuff less, wear it longer, and buy less. The volume is cranked up on capitalism right now and that’s what makes simple things like this so difficult. Buying less is a communications issue. If we could tell the story better it would help.

What is one thing that discourages you about the fashion industry and one thing that encourages you?

I dislike the fast fashion attitude. All apparel companies are in it somehow – some more than others. I don’t know where this attitude came from of needing to wear something different every day. When you go to Europe they have fewer clothes and they buy things that are really right for them. It’s disheartening for women’s self image that people get so wrapped up in how they look that it becomes disempowering. It saddens me because women lose so much potential to fast fashion.

What I love seeing is work like what the Sustainable Apparel Coalition is doing with the HIGG Index. They’re bringing 200 plus companies and competitors together and really trying to solve the issue of fashion transparency. Also, technology. Bioengineering and biotech is exciting and gives me hope [more on this in her talk notes].

If I could go back in time – I’d be a biologist.

Her talk

The fashion industry at-a-glance

- People know more instinctively about unfair labor practices, but not as much about sustainability in fashion.

- It takes about 700 gallons of water to produce a single garment.

- Of the thousands of dyes on the market, only about 10 are nontoxic [aka – a pair of leggings is more like a nicorete patch that is absorbing through your skin].

- The industry must shift from industrial to innovation to impact.

- For this to happen, we have to train a corporate culture that’s been designed to focus on growth to focus on consequences.

- By 2030 – 20% of our clothing will have wired technology in it. Data is the new oil.

The radical people and ideas changing the industry

Now:

- The BF+DA, obviously 🙂

- Eileen Fisher – her Vision2020 challenge is setting a radical goal of using all organic materials.

- Patagonia – for its pioneering work in advocating repair and recycling of garments.

- Levi’s – they’re trying to take the water out of jeans manufacturing.

Next gen biotech:

- Bionic Yarn – is pulling plastics out of the oceans and weaving it into yarn [Pharrell use this in his denim line].

- Billie Whitehouse – is a quirky designer weaving GPS into jackets.

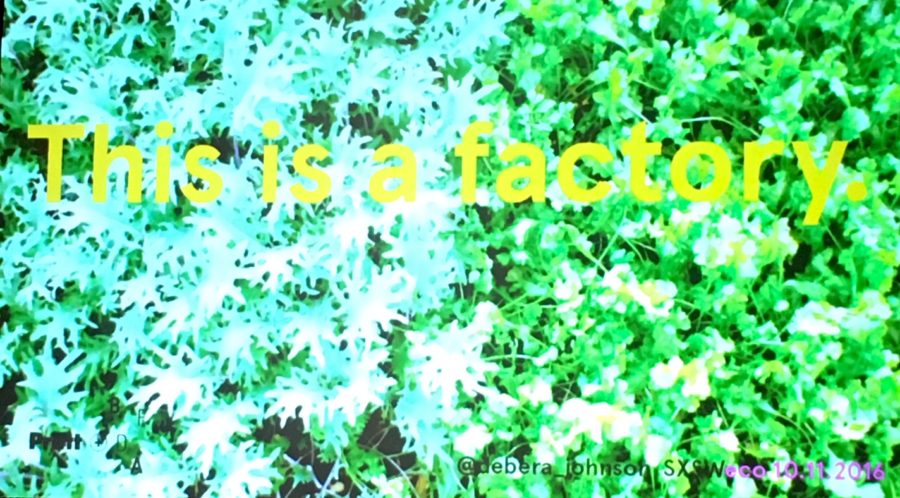

- Modern Meadow – is growing their own leather in a lab. What if there were no more need for cows and the industry shifts dramatically?

- Bolt Threads – is using Biomimicry from a spider web to create sustainable fibers.

Want more fashion tech? Francesca Willow of Ethical Unicorn wrote a piece about a cool company out of the UK called Unmade that’s manufacting custom garments on-demand. Check it out.

*I transcribed this interview and notes on the fly, so some answers may not be verbatim.

Want more sustainability insights about zero food loss, the cirulcar economy and some pointers from Bill Nye? Follow me on twitter. I’m live tweeting them from the conference with #SWSWEco.

Photos: mine, Kordal, BF+DA.